Troubleshooting For Vertical Roller Mill

𝐕𝐑𝐌

2023年6月10日 The document discusses training on troubleshooting for Loesche vertical roller mills It covers various process parameters like gas flow, temperature, differential pressure and how they are measured, controlled, and Online running condition monitoring of the vertical roller mill (VRM) is significant to assess the equipment performance degradation and reliabilityFull article: Reliability assessment of the vertical roller mill based vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS4 Vertical Roller Mill Operation Handbook Published at grampiancaredatagovuk settings, will be discussed in detail Section 2: Vertical Roller Mill Operation Procedures This section focuses on the daytoday operation of vertical roller mills, covering startup, shutdown, and routine operation proceduresVertical Roller Mill Operation Handbook

.jpg)

FOR VERTICAL ROLLER MILLS Loesche

FOR VERTICAL ROLLER MILLS by Matthias Authenrieth, Thomas Hyttrek and Andreas Reintke, Loesche GmbH, Germany, and Steven McGarel, Senior Consultant, USA LMmasterforVRMsdd 1 190612 11:46 PROCESS CONTROL INTERNATIONAL CEMENT REVIEW MAY 2012 V RMs have become the grinding2019年4月16日 Vertical roller mills (VRM) have been used extensively for comminuting both cement raw materials and minerals like limestone, clinker, phosphate, manganese, magnesite, feldspar and titanium(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from Find, read and cite all the research (PDF) Performance Evaluation of Vertical Roller Mill inDRIVE SELECTION FOR LARGE LOESCHE VERTICAL ROLLER MILLS M Keyßner, T Fahrland, Loesche GmbH, Duesseldorf, Germany ANTRIEBSAUSWAHL FÜR GROSSE VERTIKALROLLEN MÜHLEN DER BAUART LOESCHE 42 CEMENT INTERNATIONAL 4 2/2016 4 VOL 14 Rising demand from the cement industry for ever greaterDRIVE SELECTION FOR LARGE LOESCHE VERTICAL ROLLER MILLS

36.jpg)

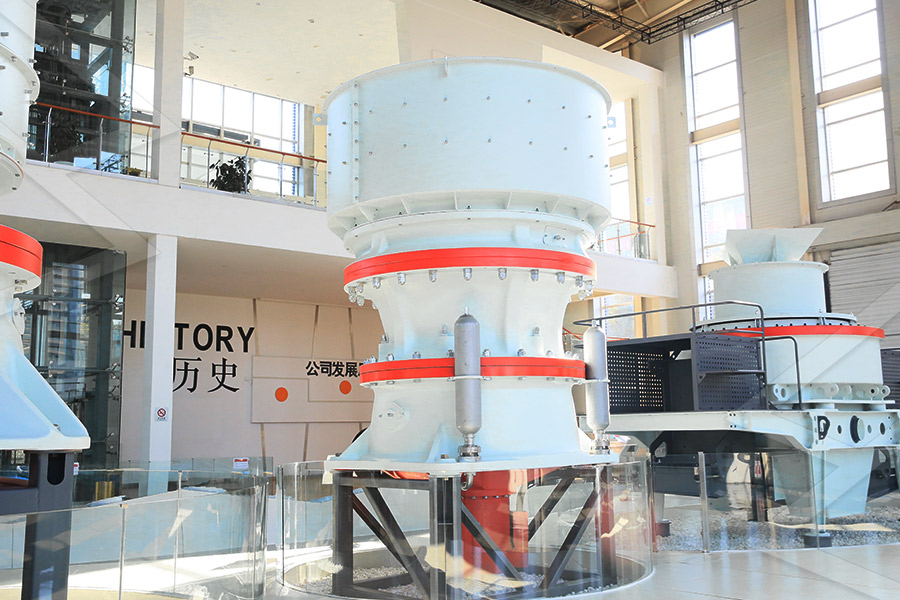

Vertical Roller Mills used for the comminution of mineral ores

The Pfeiffer pilot mill used in this study is a semiindustrial vertical roller mill of type MVR with a table diameter of 400 mm The mill can be equipped with different classifiers for specific applications The process layout of the plant (Figure 2) corresponds to that of an industrial plantIncrease the energy efficiency of your vertical roller mill Reducing energy consumption is a top priority for both environmental and economic reasons But you can't afford to lose performance in your VRM Our MAAG® GEAR CEM Drive system achieves both, powering VRMs up to 14 000 kW with a compact integrated motor that reduces power loss by more than 20%MAAG® GEAR CEM DriveOverview of Vertical Roller Mill (VRM) A Vertical Roller Mill (VRM) is an advanced and efficient grinding machine commonly used in the cement industry for grinding raw materials and clinker VRMs have become increasingly popular due to their ability to produce finer products with lower energy consumption compared to traditional ball millsVertical roller mill vs ball mill for cement grinding: Comparison SikaGrind® FOR VERTICAL ROLLER MILLS Pilot Mill (Picture: Loesche GmbH, Germany) The production of Portland Cement (OPC, CEM I) with Vertical Roller Mills can demand the following benefits from a Grinding Aid: ́ Increased production rate energy saving ́ Higher fineness faster strength development ́ Reduced vibration less wearPicture: Loesche GmbH, Germany CEMENT SikaGrind® FOR VERTICAL ROLLER MILL

.jpg)

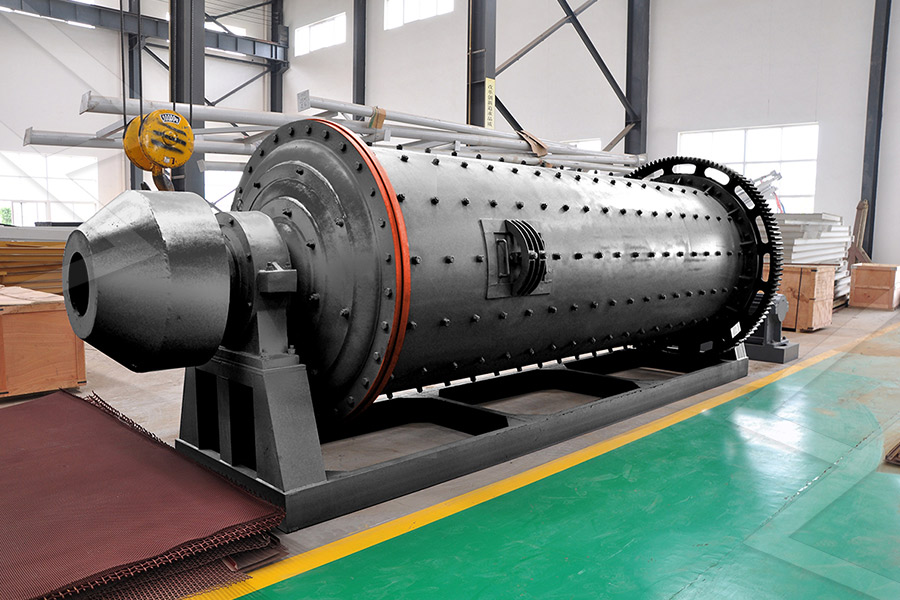

Cement grinding Vertical roller mills VS ball mills

Vertical roller mills and ball mills represent two clearly distinct technologies However, with proper adjustments to the operational parameters of the vertical roller mill almost identical cement properties can be achieved by the two mills Vertical Roller Mills (VRM) represent the most widely spread milling technology for raw materials in the cement industry and for many years also for clinker and slag grinding The availability of a VRM largely depends on the driving gear For mills RENK2001年10月1日 Vertical roller mills (VRM) have been used extensively for comminuting both cement raw materials and minerals like limestone, clinker, phosphate, manganese, magnesite, feldspar and titaniumLOESCHE vertical roller mills for the comminution of2021年1月1日 Vertical roller mill has proved to be a popular choice for finished cement grinding over all other machineries due to advantages like low power consumption, higher capacity, process simplifications and compactness but it is also very sensitive to vibrations and can deteriorate productivity if process optimization is varied slightlyReview on vertical roller mill in cement industry its

.jpg)

Vertical roller mills FLSmidth Cement

As vertical roller mills are 30 to 50 percent more efficient than other grinding solutions, they give cement plant owners a great opportunity to maximise productivity and minimise operating costs The high energy efficiency is especially beneficial in regions with limited power generating capacity or where electricity availability is limited2001年10月1日 LOESCHE vertical roller mills are widely used for the comminution of raw materials in the cement industry, for the comminution of clinker and blast furnace slag and for the production of pulverized coal for cement kilns, blast furnaces and power plantsLoesche vertical roller mills for the comminution of ores and minerals Attendees will be trained on maintenance procedures and preventative maintenance of equipment, including safety issues Instruction will be provided on inspections, troubleshooting, and failure analysis Topics Covered: Equipment: Vertical Mills, Vertical Mill Separators; Equipment Design and Fundamentals; Main Components and Component DetailsVertical Mill Maintenance Seminar FLSmidth Cement2023年10月3日 Unveiling the Vertical Roller Mill In the everevolving world of industrial machinery, vertical roller mills (VRMs) have gained immense popularity for their efficiency and versatility This powerful milling machine is used across various industries, including cement, mining, and chemicals, to grind raw materials and achieve finely ground productsWhat is a vertical roller mill (VRM)? A Comprehensive Guide to

.jpg)

Vertical roller mill, Vertical roller grinding mill DirectIndustry

Find your vertical roller mill easily amongst the 14 products from the leading brands (FLSmidth DorrOliver Eimco, FLSMIDTH, ) on DirectIndustry, the industry specialist for your professional purchasesWe can design and manufacture vertical roller mills of diversified specifications and models for raw meal, cement, and slag comminuation systems in cement clinker production lines with capacity up to 10,000t/d To continuously meet the needs of grinding various materials Home;Vertical Roller Mill (VRM)SinomaLiyang Heavy Machinery Co, Ltd2017年4月1日 Separation operation of verticalrollermill will be modelled by application of current models The model shall enable the prediction of the throughput, the particle size distributions around the verticalrollermill circuit, the specific energy consumption and in a later stage the wear to be expected in dependency of ore treatedOperational parameters affecting the vertical roller mill a Loesche mill, with a grinding track diameter of only 11 metres, was used as long ago as 1935 However, the breakthrough in grinding this type of material on the vertical roller mill did not take place until the beginning of the 1990’s 1935 The first Loesche mill for grinding cement clinker, an LM 11, was commissioned in Joao Pessao, Brazil2 µm 5 µm Loesche

Plant engineering solutions for any mission Loesche

Since 1906 worldwide market leader in designing, manufacturing and servicing vertical roller mills for the cement, power and industrial minerals industries Plant engineering solutions for any mission Loesche2023年6月10日 The document discusses training on troubleshooting for Loesche vertical roller mills It covers various process parameters like gas flow, temperature, Germany gajewski@loesche loesche Training on The Job Trouble Shooting Loesche Vertical Roller Mill LM 564 / LM 353 D / 563 + 3 C/S for Pearl Dhar Cement plant 2𝐕𝐑𝐌 How to improve vertical roller mill lifecycles Global Cement Maganzine December 2014 [5] Baechler, M: Pushing limits Word Cement December 2016 [6] Reichardt, Y: The new PFEIFFER roller mill ZKG International No 112010 [7] Sachse, C O Assmann:Drive Systems for Vertical Roller Mills2023年12月4日 A vertical roller mill (VRM) is a grinding equipment used for the size reduction of minerals, cement, and ceramics The capacity of the VRM depends not only on the grinding material properties but also on the operational parameters of the VRM This study investigatedNumerical Investigation of Vertical Roller Mill Operation Using

.jpg)

SikaGrind® for vertical roller mills

4 SikaGrind® FOR VERTICAL ROLLER MILLS Pilot Mill (Picture: Loesche GmbH, Germany) The production of Portland Cement (OPC, CEM I) with Vertical Roller Mills can demand the following benefits from a Grinding Aid: ́ Increased production rate, energy saving ́ Higher fineness, faster strength development ́ Reduced vibration, less wearAs the acknowledged leader in fluid bed roller mill design, Williams Roller Mills provide years of reliable, consistent, and efficient operation However, what truly sets our equipment apart is their ease of use and maintenance Learn more about the features of the Williams Patent Crusher vertical roller mill to see why it should be your top Industrial Roller Mills Williams CrusherA vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, metallurgy, construction, chemical industry, and other industries to make powder, especially for materials such as cement clinker, coal Energysaving and Efficient Vertical Roller Mill Fote MachineryVertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation About 14million US$ [Newlybuilt] and about 230 million US$ [retrofitted], including the cost of supplemental facilities [200tRM/h] [1US$=¥110] Related matters Vertical roller mill for raw Application p rocess materials

.jpg)

Vertical roller mill routine maintenance note PDF

2014年2月25日 Vertical roller mills are used in stone production lines for crushing and grinding tasks Proper maintenance of the vertical roller mill equipment is important, including maintenance of bearings, routine Atox Vertical Roller Mill, Maintenance and Repair Free download as Powerpoint Presentation (ppt), PDF File (pdf), Text File (txt) or view presentation slides online The document discusses maintenance and repair of an ATOX Vertical Atox Vertical Roller Mill, Maintenance and RepairThe vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc The VRM cement mill has a Vertical Roller Mill Operation in Cement Plant2005年1月1日 Vertical roller mills are used in the cement industry for grinding cement raw material, coal, pozzolana and blastfurnace slag and for the finish grinding of cementHigh efficiency classifiers for MPS vertical roller mills

.jpg)

Vertical Roller Mill Common Problems And Solutions

2014年8月28日 1 A vertical mill, grinding roller The liner wear repair Plate vertical roller mill body and wear resistant lining board in the use process, due to the roller pressure roller; the material force; friction between the material and the mill lining board; the material grinding angle caused by the grinding roller shear stress; Hydraulic system pressure; synthetic vertical mill 4 SikaGrind® FOR VERTICAL ROLLER MILLS Pilot Mill (Picture: Loesche GmbH, Germany) The production of Portland Cement (OPC, CEM I) with Vertical Roller Mills can demand the following benefits from a Grinding Aid: ́ Increased production rate, energy saving ́ Higher fineness, faster strength development ́ Reduced vibration, less wearSikaGrind® for vertical roller millsLower operating costs: Vertical roller mills have lower operating costs than traditional mills due to their lower power consumption, maintenance costs, and overall footprint Higher grinding capacity: Vertical roller mills can handle up to 25% more capacity than traditional mills, making them ideal for large cement plants with high throughput requirementsHow does Vertical Roller Mill Work? ball mills supplierAutomatic Equipment is the nation’s leading provider of livestock roller mills, rotary mills, hammer mills, and other industrial grinding mills Farmers choose our grain processing equipment for beef, pork, dairy or poultry farming Get more from your grain with Automatic feed millsLivestock Roller Mills Grain Processing Equipment Automatic

.jpg)

A datadriven decisionmaking framework for online control of vertical

2020年3月1日 Vertical roller mill (VRM) is a largescale grinding equipment, which is used to grind raw materials from block/granule into powder Due to harsh production environment and inconsistent raw